Cleaning Machines

Our line of cleaning machines are designed for a variety of applications and can be used to clean paint, wallpaper, textile, ink and more. Systems can be designed to use aqueous, caustic, or solvent-cleaning chemistries – we can help you determine what will be most effective for removing your contaminants.

Our Machines

Cleaning Applications

Gemini Techniek produces customer-specific cleaning applications for various industries.

The industries for which Gemini Techniek supplies the cleaning applications are:

Paint & Coatings Industry

For the paint & coatings industry, Gemini Techniek can offer cleaning/washing machines for open-top mobile vessels.

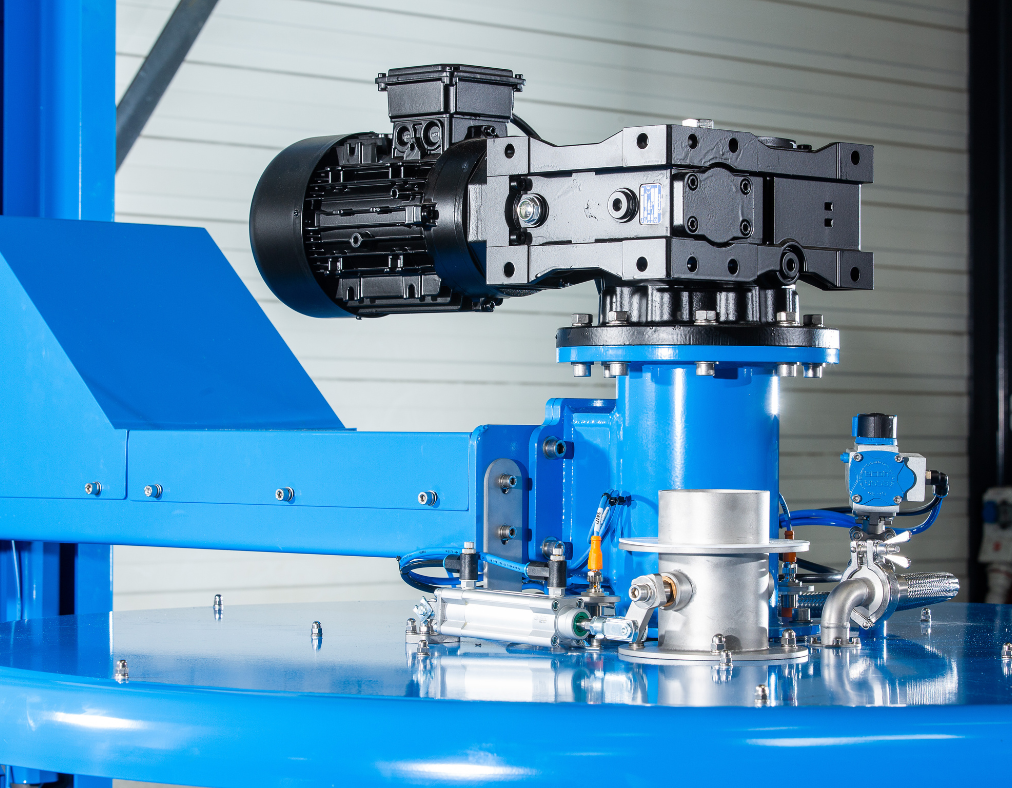

The vessel washer of Gemini offers customers a labour-friendly and safe solution for the cleaning of various types of production vessels containing resins of paint or other chemicals. Because the washing machine cleans the vessels fully mechanically, production workers are no longer exposed to chemical fumes during the cleaning process and the physical work is reduced. As a result, the GemiClean VW results in safer production processes and better working conditions.

With the GemiClean VW-S (small) model also 200 ltr. drums without outlet can be handled. For smaller drums/containers we have the GemiClean DW (drum washing machine) model available.

Wallpaper & floor covering Industry

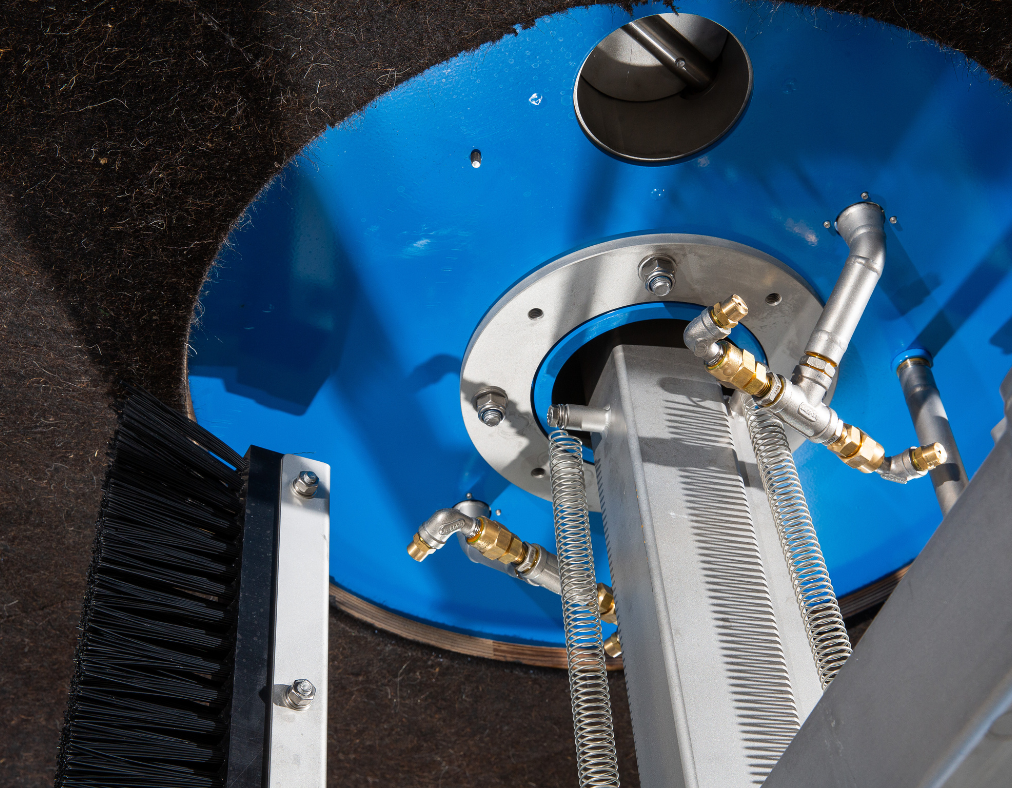

Gemini Techniek has successfully introduced washing machines for rotary screens & squeegees in the wallpaper industry. The GemiClean SW (for rotary screens) & GemiClean RW (for squeegees) are very efficient and high-performance cleaning machines. Both washing machines are developed in conjunction with the input and knowledge of different European wallpaper manufacturers. Typical feature of the GemiClean SW for example is the vertical position of the washing cabinets to prevent the screens from getting damaged during loading and unloading. In addition to this there are no moving parts in the polluted area of the washing machine. A typical feature of the GemiClean RW is the high-pressure cleaning of both the inside and outside of the squeegee. The machine is dedicated to cleaning squeegees only and up to 6 squeegees can be cleaned during one wash cycle.

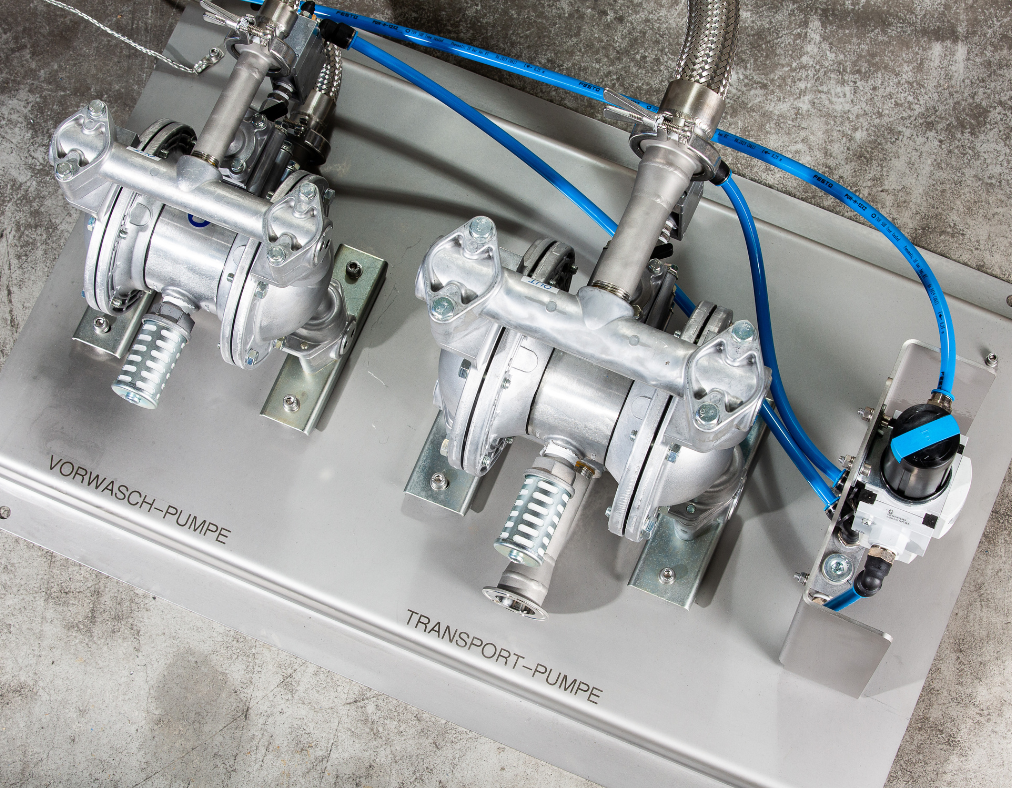

The GemiClean CW washing machine combines cleaning of screens & squeegees. With the GemiClean VW (vessel washing machine) mobile vessels can be cleaned. In order to clean the inside of 75 ltr. & 300 ltr. tubs used on the Gemini WPD dispensing system for PVC plastisol, we have developed the GemiClean TS (tub scraping) machine. This machine can be delivered in a semi-automatic execution where the handling of the tubs is manually.

We also have a fully automatic model available were dirty tubs are automatic conveyed to the cleaning station and automatically discharged after the cleaning process. Cleaning based on rotating scrapers combined with a spray nozzle system.

Textile Industry

For the textile industry the same washing machines can be used. Rotary screens can be cleaned / washed using the GemiClean SW and squeegees can be cleaned using the GemiClean RW washing machine. The GemiClean CW washing machine combines cleaning of screens & squeegees. The GemiClean DW (drum washing) machine can be used in order to clean e.g. plastic 60 ltr. & 120 ltr. tubs commonly used in this industry.

With the GemiClean VW (vessel washing machine) mobile vessels can be cleaned. All washing machines can handle water or other cleaning liquids like solvents. Washing machines are also available in explosion proof execution (ATEX).

Explosion proof

The cleaning machines can be executed in explosion proof according to ATEX in category 1 / 2/ 3. It can also be executed in Class 1 Division 1 (or 2). Gemini can provide their machine in the right category according to the environment of the customer.